Safety of Auburn Railroads

February 28, 2023

A massive train crash released toxic chemicals into the atmosphere in East Palestine, Ohio. Train cars carrying toxic chemicals had to be burned off to prevent an explosion, leading to the surrounding area getting contaminated. This may lead to the question; Is our local railroad safe?

Union Pacific is the operator of the Roseville Subdivision, the railway line between Roseville and Truckee. The line goes over the historic Donner pass built for the transcontinental railroad. The historic grade has a relatively clean track record with minimal accidents.

In order to increase the speed of trains on the steep mountain pass many safety improvements have been installed.

A basic improvement to the rail line over the pass was to convert the wooden ties to concrete ones. Ties are the beams that keep the rails together, and with concrete ones, the rail is more stable and doesn’t rot or burn like the wooden ones. The concrete ties allow for higher speeds and safer rides.

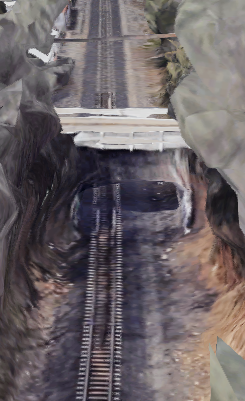

Brook Road is a road with an overpass that is just north of Placer High school. The railroad takes a sharp curve under the bridge. This creates a risk, as if the train derails under the bridge, it might strike the pillars on the bridge and injure anyone on the bridge’s deck. To mitigate this risk, the railroad has installed a “Check Rail”, which is a 3rd rail placed on the inside of the tracks to push the wheels towards the tracks in case of derailment.

(Google Earth imagery of Check Rail)

Another major safety improvement is the implementation of defect detectors along the line. These detectors are simple. They are simple metal beams that are in between the rails that the inside of the wheel hits. While simple, this sends vital data to the dispatch. Knowing how many times the wheels hit the bumper, dispatch can count the number of cars and compare it to the last detector, and if the variables are different, then the dispatch knows there is a problem. This type of detector can also sense dragging objects, as they can hit the beam as well.

To keep the noise generated by the steel wheels hitting the steel rails down, Union Pacific has installed grease machines. These devices slowly pump grease onto the rail. The placement of these machines is right before tight curves, which prevents friction from creating sparks or loud squealing. This device is solar powered, with a solar panel usually nearby for power. This allows for it to be operated without human interference or the risk of shutting down due to blackouts.

(Google Earth imagery of Grease Machine)

While the tracks are relatively safe now, concerning patterns in the railroad industry grow. A new policy that railroad companies are adapting is called “Precision railroad scheduling”, which is a program intended to increase profits and efficiency of trains as much as possible.

One of these changes includes limiting train crews from two or three down to only one crew member. With only one driver, simple safety procedures cannot be done, like the conductor getting out of the train to inspect it as the driver rolls by. Another major drawback is that people may be in the cab isolated for long periods of time, leading to decreased mental states of drivers. Another safety drawback is that if the driver makes a mistake, then they cannot be corrected by a colleague.

Another problem with PSR is that trains are operated at a lesser frequency in exchange for longer trains. Trains now regularly extend 150+ cars. The railway industry is the safest way for chemical companies to ship their goods, but if an accident happens, the length of these trains can quickly become dangerous.

So, is the railroad line in Auburn safe? Yes, thankfully. Our local railroad has invested millions into safely operating trains over the past, and legislation is being proposed to ban single-person crews in trains carrying toxic chemicals.